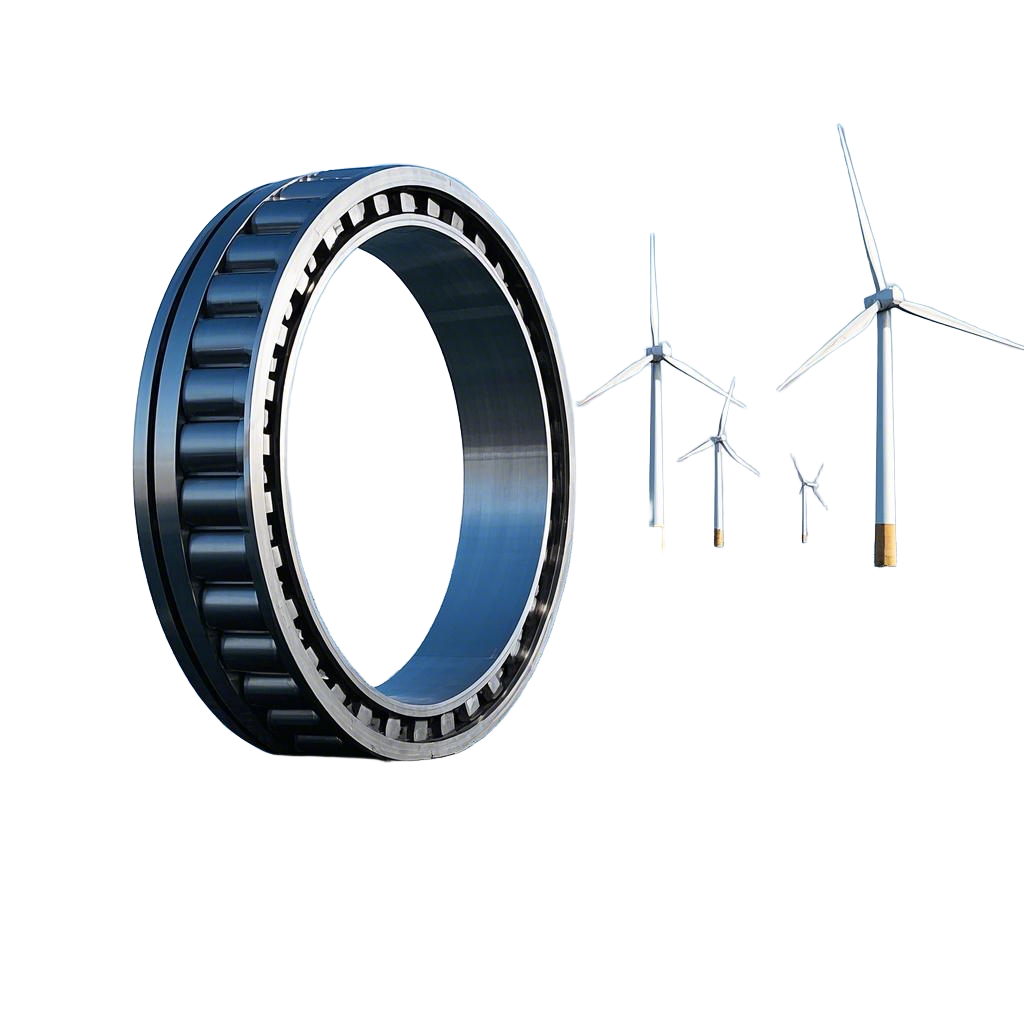

The three row cylindrical roller main bearing achieves relative motion by rolling the rollers between the raceway of the inner and outer rings. When the shaft is subjected to radial load, the radial rollers bear the radial force and transmit the force to the inner and outer rings; When the shaft is subjected to axial load or overturning moment, the axial rollers bear the corresponding force, enabling the bearing to stably support the operation of the shaft. Under the action of the cage, the rollers can be evenly distributed on the raceway, ensuring the uniform transmission of load and reducing local stress concentration.

Service Hotline:

+86 15225525908

Service Time:

8:00–20:00

Email:

tuodajuyuan@gamail.com

Service Hotline:

+86 15225525908

Service Time:

8:00–20:00

Email:

tuodajuyuan@gamail.com

TUO DA JU YUAN:

Hainan Tuoda Juyuan Slewing Ring Co., Ltd. mainly engages in the R & D, manufacturing and sales of large – scale slewing rings, wind power bearings and other products. It is an innovative leading enterprise in multiple industries. Led by scientific and technological innovation, the company has established multiple R & D centers, obtained 79 patents, and passed a number of authoritative certifications. Based in Hainan and facing the world, the company cooperates with well – known enterprises to promote its international development.

Company address:

- 4#, Longhua Digital Economy Industrial Park,

- Haixiu Avenue, Haikeng Sub – district, Longhua District,

- Haikou City, Hainan Province

NAVIGITION:

Quality determines everything

Innovation secures the future

Copyright © 2025 by Tuoda Juyuan