brief introduction

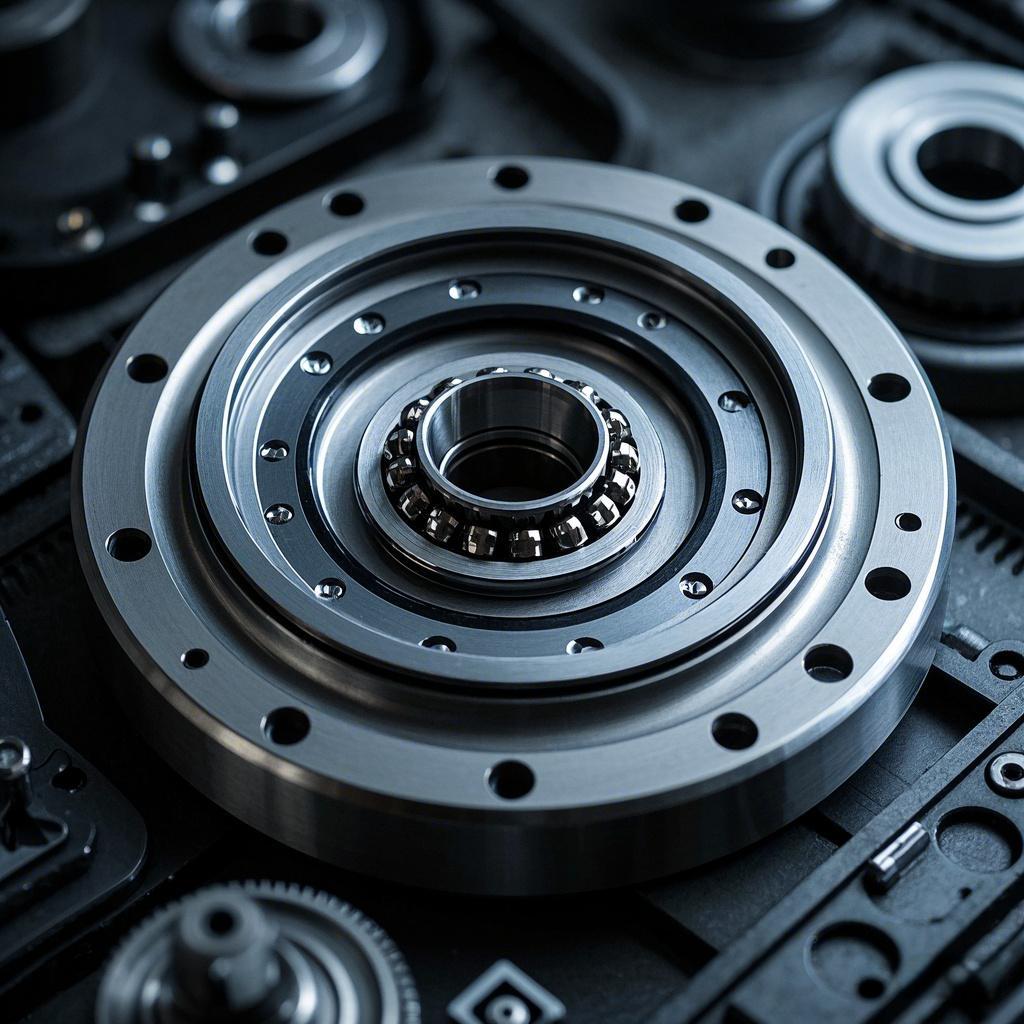

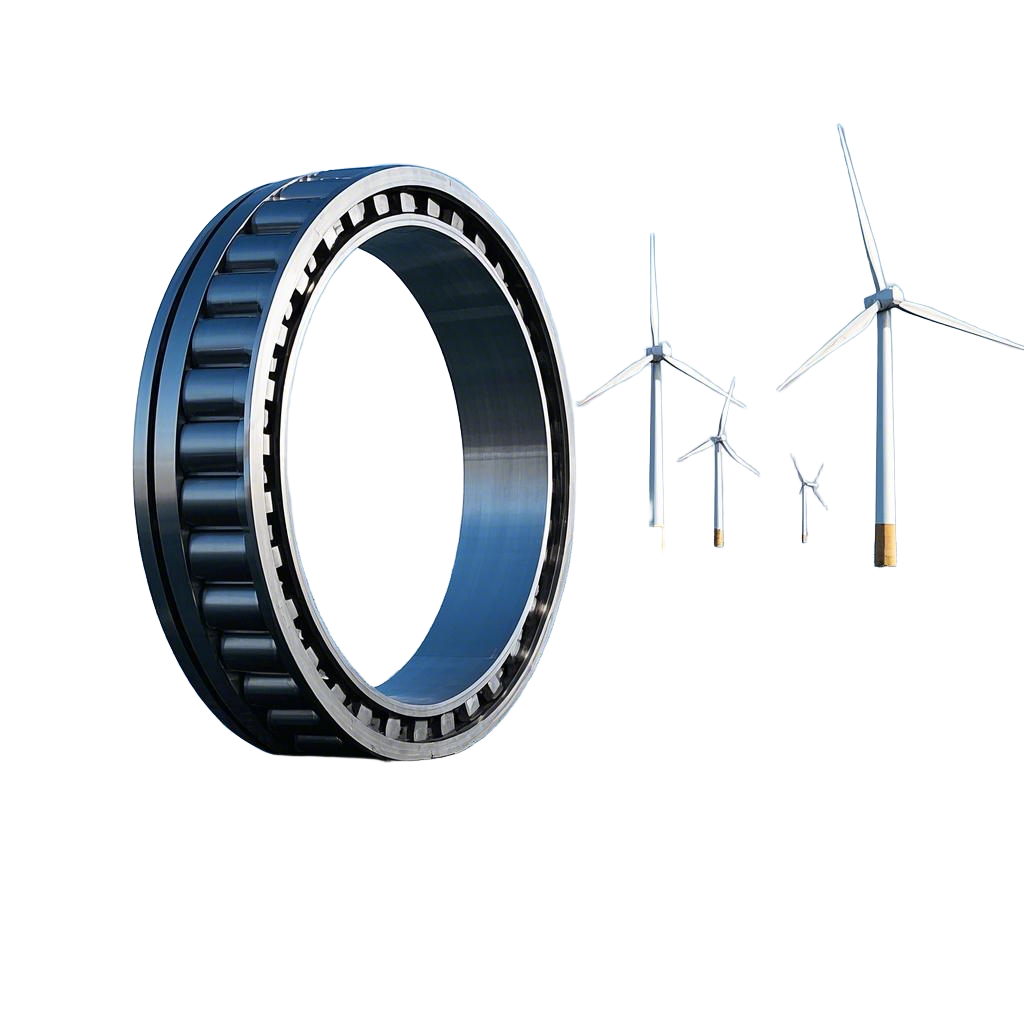

- Yaw bearing is a special type of bearing mainly used to withstand combined radial and axial loads, with high precision and stability requirements. In wind turbines, the yaw bearing is installed on the nacelle base,

Used to support the entire cabin and ensure the directionality of the pod to the positive wind force through yaw adjustment, so that the cabin axis can track the changing and stable wind direction. At the same time, the cable is automatically untied when the cable from the cabin to the tower bottom reaches the set twist angle.