Rotary bearings: single row ball bearings (01 series, HS series, Q series), double row ball bearings (02 series), three row roller bearings (13 series), single row cross roller bearings (11 series), double row ball bearings (07 series), and lightweight series rotary bearings. Series products can be provided according to the national machinery industry standard JB/T2300-2015, with product models covering various standard and non-standard specifications from 150mm to 4500mm

Single row four point contact ball type rotary bearing (01 series)

The single row four point contact ball type slewing bearing consists of two seat rings, with a compact structure, light weight, and four point contact between the steel ball and the circular arc raceway. It can simultaneously withstand axial force, radial force, and overturning moment. Construction machinery such as rotary conveyors, welding operators, small and medium-sized cranes, and excavators can all be selected.

Double row reducing ball rotary bearing (02 series)

The double volleyball type slewing bearing has three race rings, and the steel balls and isolation blocks can be directly arranged into the upper and lower raceways. According to the force conditions, two rows of steel balls with different diameters are arranged. This open assembly is very convenient, with a bearing angle of 90 ° for both the upper and lower circular arc raceways, which can withstand large axial forces and overturning moments. When the radial force is greater than 0.1 times the axial force, the raceway must be specially designed. The axial and radial dimensions of the double row reducing ball slewing bearing are relatively large, and the structure is tight. Specially suitable for tower cranes, truck cranes, and other loading and unloading machinery that require a medium or larger diameter

Single row cross roller rotary bearing (11 series)

The single row cross roller rotary bearing consists of two race rings, with a compact structure, light weight, high manufacturing accuracy, small assembly clearance, and high requirements for installation accuracy. The rollers are arranged in a 1:1 cross pattern, which can simultaneously withstand axial force, overturning moment, and large radial force. It is widely used in lifting transportation, engineering machinery, and military products.

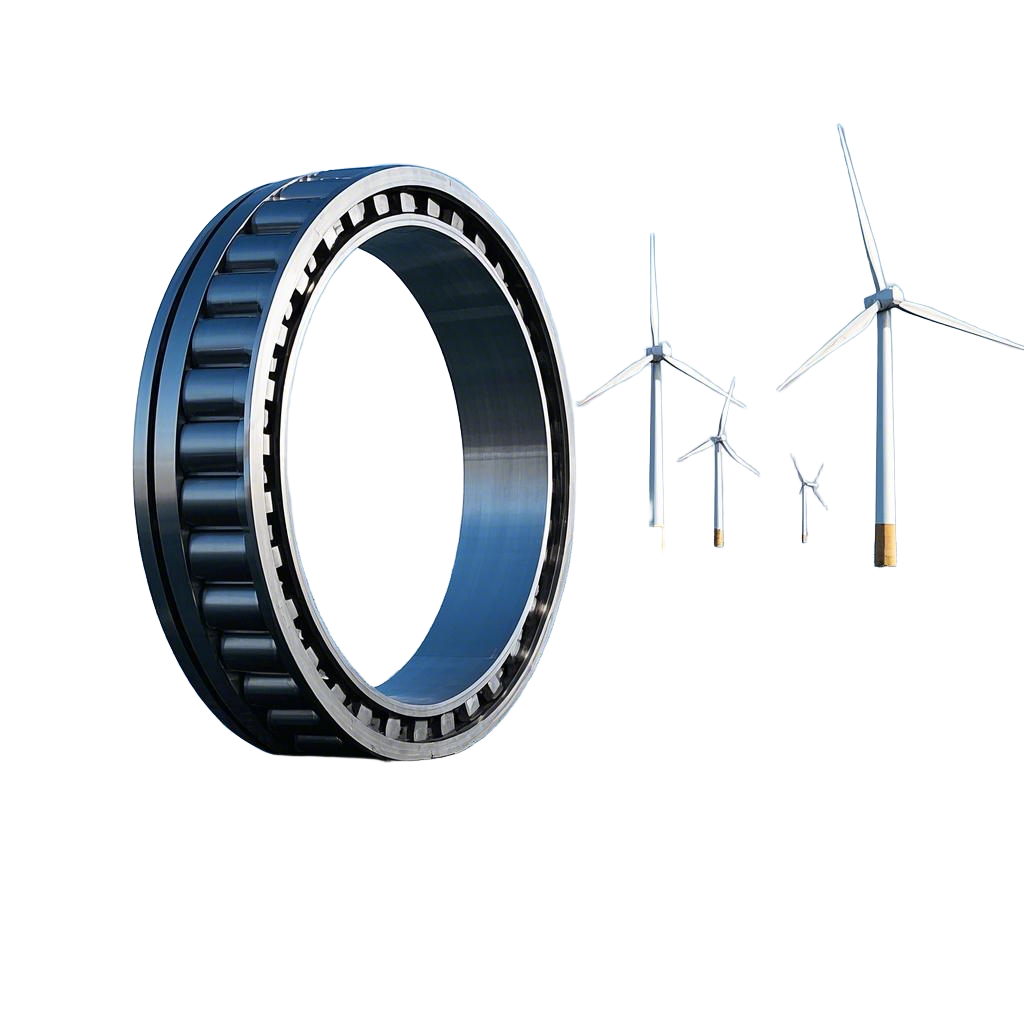

Three row roller type slewing bearing (13 series)

The three row roller type slewing bearing has three race rings, with separate upper, lower, and radial raceways, allowing the load on each row of rollers to be accurately determined. Being able to withstand various loads simultaneously, it is the product with the highest load-bearing capacity among the four types. Its shaft and radial dimensions are relatively large, and its structure is sturdy. It is particularly suitable for heavy machinery that requires larger diameters, such as bucket wheel excavators, wheel cranes, marine cranes, port cranes, steel waterway turntables, and large tonnage truck cranes.

Lightweight series slewing bearing (WD series)

Lightweight slewing bearings have the same structural form as ordinary slewing bearings, with light weight and flexible rotation. Widely used in food machinery, filling machinery, environmental protection machinery and other fields.

Single row four point contact ball type rotary bearing (HS series)

The single row four point contact ball type slewing bearing consists of two race rings, with a compact structure and four point contact between the steel ball and the circular arc raceway. Mainly used on machinery such as automobile cranes, tower cranes, excavators, pile drivers, construction vehicles, radar scanning equipment, etc. that can withstand overturning moments, vertical axial forces, and horizontal tilting forces.

Single row cross roller rotary bearing (HJ series)

The single row cross roller rotary bearing consists of two race rings, with a compact structure, high manufacturing accuracy, small assembly clearance, and high requirements for installation accuracy. The rollers are arranged in a 1:1 cross pattern, which can simultaneously withstand axial force, overturning moment, and large radial force. It is widely used in transportation, engineering machinery, and military products.

Single row four point contact ball type rotary bearing (Q series)

Single row four point contact ball type slewing bearing, consisting of two seat rings, has a compact structure and light weight. The steel ball is connected to the circular isolated raceway at four points, and can simultaneously withstand axial force, overturning moment, and large radial force. It is suitable for rotary conveyors, welding operators, small and medium-sized overweight machines, and excavators.

Ship industry slewing bearings

Standard CB/T3669-1999. Suitable for marine crane slewing bearings. Also applicable to offshore crane slewing bearings.