How can slewing bearing manufacturers improve production efficiency?

How can slewing bearing manufacturers improve production efficiency

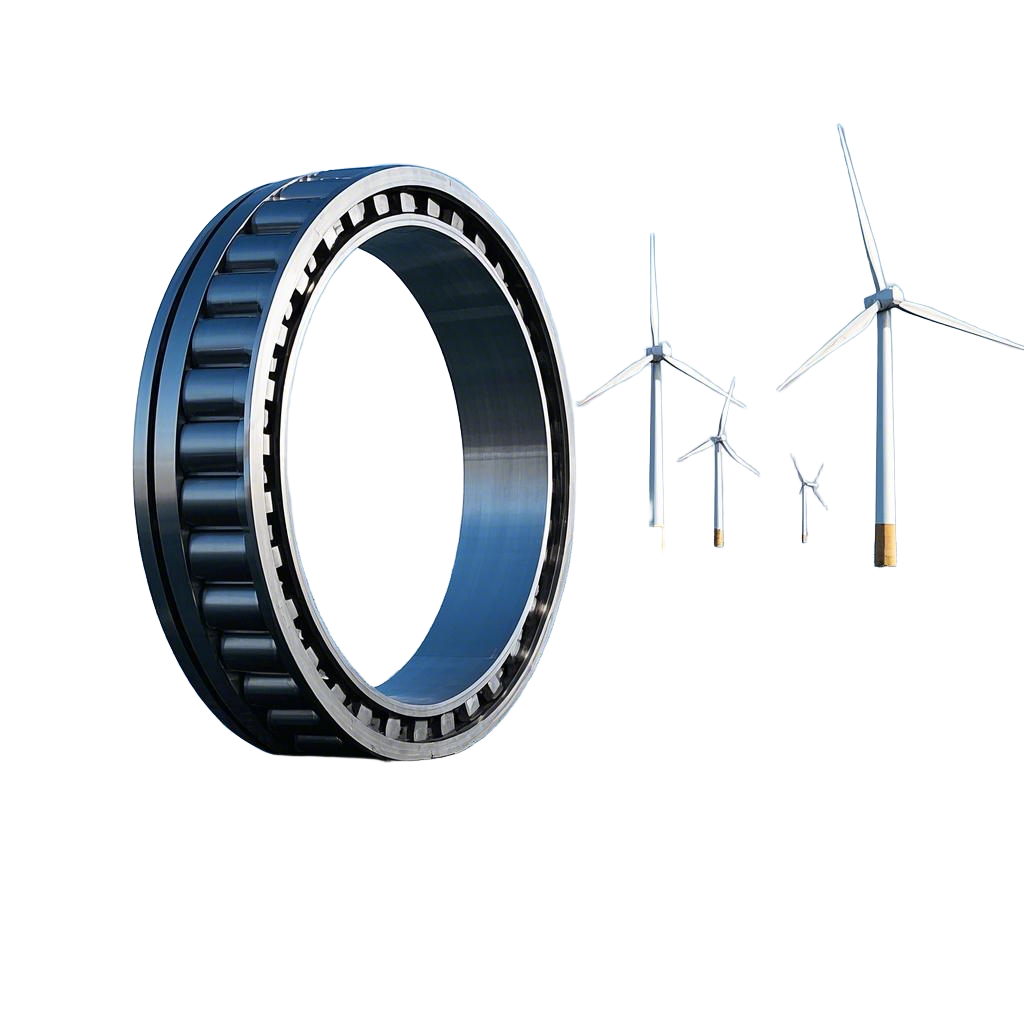

As an important mechanical component that connects rotating and fixed parts, slewing bearings have a wide range of applications in various fields such as engineering machinery, metallurgical machinery, and port machinery. For slewing bearing manufacturers, improving production efficiency is not only the key to reducing costs and enhancing market competitiveness, but also an important way to meet the growing demands of customers. This article will explore how rotary bearing manufacturers can improve production efficiency from the aspects of structural design, material selection, heat treatment process, precision manufacturing process, and production process optimization.

1. Optimize structural design

The structural design of slewing bearings directly affects their load-bearing capacity and installation convenience. In order to improve production efficiency, slewing bearing manufacturers should pay attention to the compactness and rationality of structural design. For example, adopting a multi row roller column design (such as a three row roller column) or a four point contact ball structure design can effectively disperse loads, improve overall load-bearing capacity, while reducing material usage and weight, and lowering production costs. In addition, by optimizing product design and reducing unnecessary processing steps and assembly processes, production efficiency can also be significantly improved.

2. Carefully selected high-quality materials

The selection of materials is crucial for the performance and production efficiency of slewing bearings. Rotary bearing manufacturers should choose high-quality alloy steel materials with high strength, high wear resistance, and good hardenability, such as 42CrMo, 5CrMnMo, etc. These materials not only meet the load-bearing capacity requirements of heavy machinery, but also exhibit better performance during heat treatment. By strict material screening and quality control, we ensure stable quality of raw materials and reduce production delays and cost increases caused by material issues.

3. Improve heat treatment process

Heat treatment is an important means to improve the bearing capacity and extend the service life of slewing bearings. Rotary bearing manufacturers should adopt advanced heat treatment techniques, such as surface induction hardening technology, to improve the hardness and wear resistance of the raceway. During the heat treatment process, it is necessary to strictly control the heating temperature, heating speed, and sensor quality to ensure the consistency and stability of the quenching effect. Meanwhile, tempering treatment after quenching is also essential, as it can eliminate quenching stress, improve material toughness, and prevent cracks and fractures during use.

4. Strengthen precision manufacturing processes

Precision manufacturing processes are crucial for producing high-quality rotary bearings. Manufacturers of slewing bearings should use world leading CNC machine tools and precision grinding equipment to ensure machining accuracy reaches the micrometer level. By precisely calculating and controlling the tooth profile of gears, the smoothness and dimensional tolerances of bearings, and other details, the accuracy and performance of slewing bearings can be improved. In addition, using special heat treatment techniques to optimize the internal structure of the metal can further improve the bearing capacity and fatigue strength of the slewing bearing.

5. Optimize the production process

Optimizing the production process is the key to improving production efficiency. Rotary bearing manufacturers should introduce advanced production management systems, such as ERP (Enterprise Resource Planning) systems, to achieve automation and intelligent management of production planning. Through the ERP system, enterprises can monitor production progress, inventory status, and equipment status in real time, adjust production plans in a timely manner, and reduce waiting time and waste in the production process. At the same time, ERP systems can also provide data analysis functions to help enterprises extract valuable information from production data, assist in decision-making, and improve management efficiency.

6. Strengthen employee training and technical support

Employees are the main force of enterprise production, and their skill level and work attitude directly affect production efficiency. Rotary bearing manufacturers should strengthen training and technical support for employees, improve their professional skills and operational level. By regularly organizing technical lectures, skill training, and experience exchange activities, we aim to enhance employees’ technical literacy and overall quality. At the same time, establish a comprehensive technical support system to promptly solve problems and difficulties encountered by employees in the production process, ensuring smooth production.

epilogue

Improving production efficiency is the key to the sustainable development of rotary bearing manufacturers. By optimizing structural design, selecting high-quality materials, improving heat treatment processes, strengthening precision manufacturing processes, optimizing production processes, and enhancing employee training and technical support, rotary bearing manufacturers can significantly improve production efficiency, reduce production costs, enhance product quality and market competitiveness. In the future development, slewing bearing manufacturers should continue to uphold the spirit of innovation and craftsmanship, constantly pursue excellence and perfection, and provide customers with higher quality and more efficient products and services.

Leave a Reply

Want to join the discussion?Feel free to contribute!