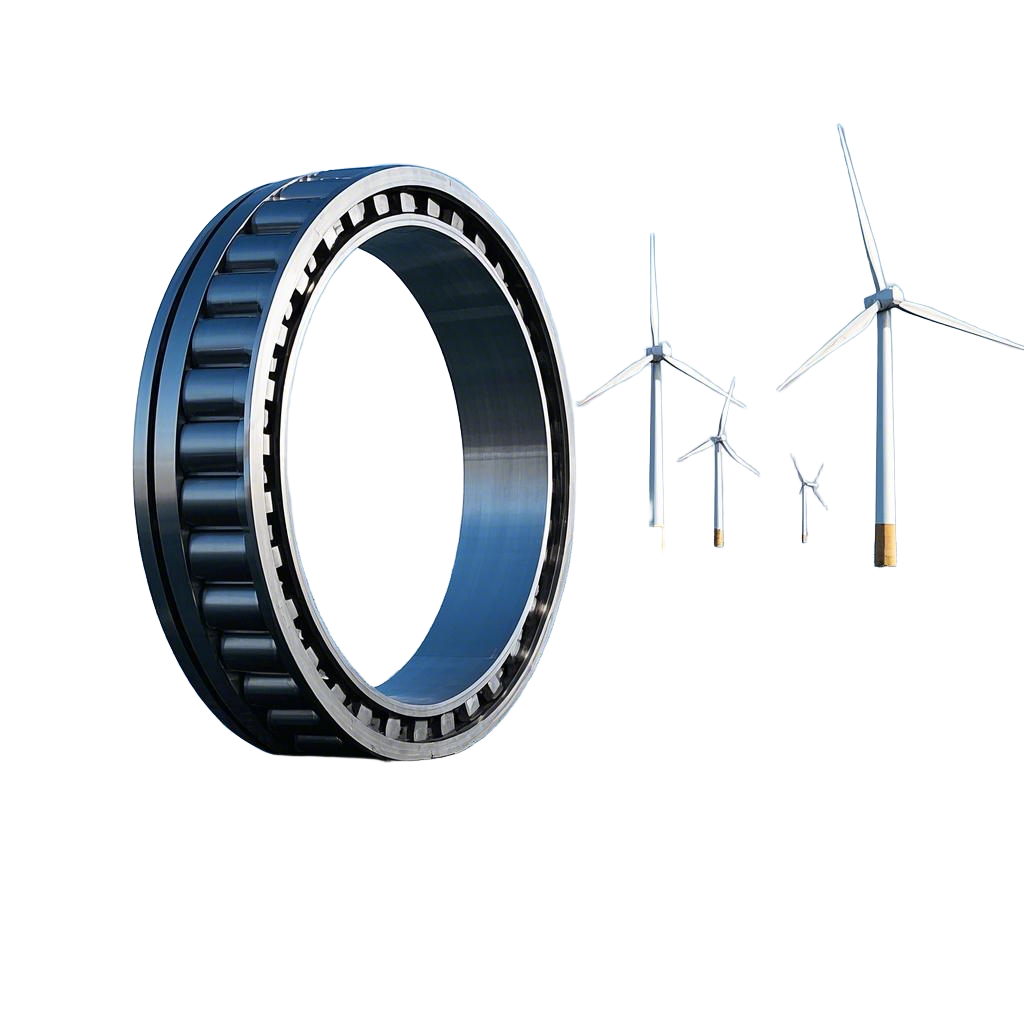

Single row tapered roller main bearings for large megawatt offshore wind turbines

- Structural optimization: Advanced technologies such as triple convex structure design and integral non expansion cage are adopted to improve the stability and reliability of bearings.

Layout form: In wind turbines, they are usually paired and installed back-to-back, which can increase the actual support distance of the bearings, reduce the bearing reaction force, and enhance the system’s ability to withstand overturning moments.

- Lubrication method: Oil lubrication is usually used, equipped with a specialized lubrication system, such as the lubrication structure invented by CRRC Zhuzhou. By setting an oil separation ring between the main bearing and the bearing seat, lubricating oil is sprayed onto the main bearing raceway and bearing rollers through the oil passage on the oil separation ring, ensuring uniform and sufficient lubrication.

Sealing system: High performance sealing components such as double lip seals, combination seals, etc. are used to prevent impurities such as seawater and sand from entering the bearing interior, while also preventing lubricant leakage.

- Induction hardening heat treatment: For example, Liebherr adopts the no soft strip induction hardening process, which requires extremely high positioning accuracy of the induction equipment, ensuring the surface hardness of the raceway and the depth of the hardened layer, and ensuring the process stability of mass production.

Ultra precision machining: The surface of the raceway is machined to a near mirror finish, effectively reducing bearing wear, minimizing energy loss during rolling, improving the lubrication effect of lubricating grease, and extending service life.

Precision machining and testing: To ensure accuracy, high-precision machining equipment and advanced machining processes are required to strictly control dimensional accuracy, form and position tolerances, etc. During the production process, advanced detection equipment such as coordinate measuring instruments and roundness meters are required to monitor and provide real-time feedback on various parameters of the bearings.

detailed information

- MW offshore wind turbine main shaft bearing: The 7MW offshore wind turbine main shaft bearing developed by China Machinery Industry Group Co., Ltd. adopts a “back-to-back” large tapered roller bearing structure, with external dimensions of Φ 3100 × Φ 2550 × 250, precision of P5 level, and a service life of more than 25 years. It has been applied in the 7MW wind turbine assembly unit of Huaneng Qidong offshore wind farm in China.

20+MW wind turbine main shaft bearings: Luoyang Axis Group has developed 20+MW wind turbine main shaft bearings for the world’s largest wind turbine manufacturer, using a new structure of long-life and high reliability tapered roller bearings. The overall accuracy reaches P5 level, and some accuracy reaches P4 level 5.

Material parameters

- Ring material: High strength, high wear resistance, high corrosion resistance, and high fatigue resistance high-quality bearing steel are generally selected, such as specially treated chromium molybdenum alloy steel, to ensure stable performance in long-term heavy load and humid corrosive environments.

Roller material: Similar to ring material, it needs to have good wear resistance, fatigue resistance, and dimensional stability. Special bearing steel materials are often used and undergo precision machining and heat treatment processes.

Retaining frame material: For extra large tapered roller bearings, the retaining frame often adopts a pillar welded structure, and the material is usually carbon steel or alloy steel with certain strength and toughness. The surface may be treated with copper plating, zinc plating, etc. to improve wear resistance and corrosion resistance.

manufacturing process

- Induction hardening heat treatment: For example, Liebherr adopts the no soft strip induction hardening process, which requires extremely high positioning accuracy of the induction equipment, ensuring the surface hardness of the raceway and the depth of the hardened layer, and ensuring the process stability of mass production.

Ultra precision machining: The surface of the raceway is machined to a near mirror finish, effectively reducing bearing wear, minimizing energy loss during rolling, improving the lubrication effect of lubricating grease, and extending service life.

Precision machining and testing: To ensure accuracy, high-precision machining equipment and advanced machining processes are required to strictly control dimensional accuracy, form and position tolerances, etc. During the production process, advanced detection equipment such as coordinate measuring instruments and roundness meters are required to monitor and provide real-time feedback on various parameters of the bearings.

Offshore floating crane slewing support

The main shaft of a shield machine

The main shaft of a shield machine

Scroll to top