How do slewing bearing manufacturers ensure timely delivery?

How can slewing bearing manufacturers ensure timely delivery

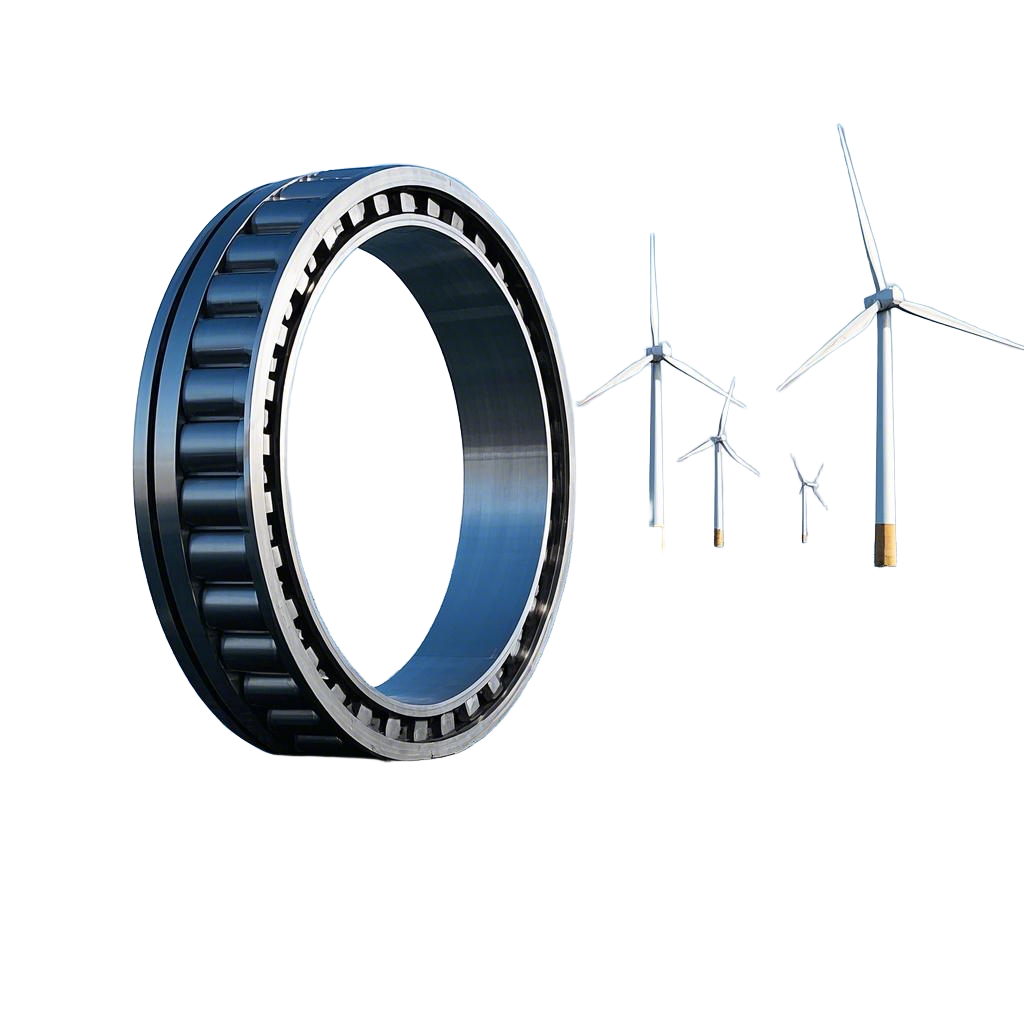

In the field of mechanical equipment manufacturing, as a key component, the timely delivery of slewing bearings has a crucial impact on the overall production process and customer satisfaction. In order to ensure timely delivery, the slewing bearing manufacturer needs to start from multiple aspects and build an efficient and rigorous supply chain management system.

1、 Strengthen the alignment between production planning and market demand

Firstly, the slewing bearing manufacturer should develop a scientifically reasonable production plan based on market demand and sales plans. By accurately predicting changes in market demand and adjusting production plans in a timely manner, we ensure that production capacity matches market demand. At the same time, maintain close communication with downstream customers, timely understand changes in customer needs, in order to flexibly adjust production plans.

2、 Optimize production processes and techniques

The production process of slewing bearings is complex and involves multiple links. In order to ensure timely delivery, manufacturers need to continuously optimize their production processes and techniques to improve production efficiency. By introducing advanced production equipment and technology, production automation and intelligence can be achieved, reducing the impact of human factors on the production cycle. At the same time, strengthen the monitoring and management of the production process to ensure that each production link can proceed smoothly according to the predetermined plan.

3、 Strengthen supplier management

The performance progress and quality of suppliers directly affect the delivery time of slewing bearings. Therefore, manufacturers need to strengthen their management of suppliers to ensure stable and reliable supply of raw materials and components. Establish long-term stable cooperative relationships with suppliers, sign clear procurement contracts, and specify delivery time and quality requirements. At the same time, regular evaluations and assessments of suppliers are conducted to ensure that they can provide the required materials on time, with quality and quantity.

4、 Establish an efficient logistics system

The logistics process is also one of the important factors affecting delivery time. Rotary bearing manufacturers need to establish an efficient logistics system to ensure that products can be delivered to customers in a timely and accurate manner. By optimizing the logistics network layout, selecting appropriate transportation methods and routes, and reducing transportation time and costs. At the same time, strengthen the tracking and management of logistics information to ensure transparency and visualization of the logistics process.

5、 Strengthen internal communication and collaboration

Communication and collaboration among various departments within the enterprise are also important guarantees for ensuring timely delivery. Rotary bearing manufacturers need to strengthen communication and collaboration between production, sales, procurement, logistics and other departments to ensure smooth information flow between each link. By establishing a sound internal communication mechanism, problems and difficulties that arise during the production process can be resolved in a timely manner to ensure the smooth execution of production plans.

6、 Introducing advanced information management systems

With the development of information technology, the application of information management systems in enterprise management is becoming increasingly widespread. Rotary bearing manufacturers can introduce advanced information management systems, such as ERP (Enterprise Resource Planning) systems, SRM (Supplier Relationship Management) systems, etc., to achieve information management in various aspects of production, sales, procurement, logistics, etc. Through an information management system, key data such as production progress, inventory status, and logistics information can be monitored in real time, providing strong support for enterprise decision-making.

7、 Cultivate a high-quality workforce

Employees are one of the most valuable resources of a company. In order to ensure timely delivery, the slewing bearing manufacturer needs to cultivate a high-quality workforce. By strengthening employee training and education, improving their professional skills and professional ethics, employees can be competent in their respective job positions. At the same time, establish a sound incentive mechanism and assessment system to stimulate employees’ work enthusiasm and creativity.

In summary, in order for slewing bearing manufacturers to ensure timely delivery, they need to start from multiple aspects such as production planning, production processes, supplier management, logistics systems, internal communication, information management systems, and employee team building. By building an efficient and rigorous supply chain management system, we aim to improve production efficiency and delivery capabilities, and meet customer needs and expectations.

Leave a Reply

Want to join the discussion?Feel free to contribute!