What are the differences and application scenarios between slewing bearings and roller bearings?

The difference and application scenarios between slewing bearings and roller bearings

In the field of mechanical transmission, slewing bearings and roller bearings are two common types of bearings, each with unique characteristics and a wide range of application scenarios. This article will delve into the differences between slewing bearings and roller bearings, as well as their applications in different fields.

1、 Structural form and composition

The structural form of roller bearings is relatively simple, mainly composed of inner and outer cylindrical bodies and several rows of rollers. When subjected to radial loads, the rollers roll inside the cylinder, reducing friction and achieving the purpose of bearing force. There are many types of roller bearings, including cylindrical roller bearings, tapered roller bearings, needle roller bearings, etc., each type is suitable for different application scenarios.

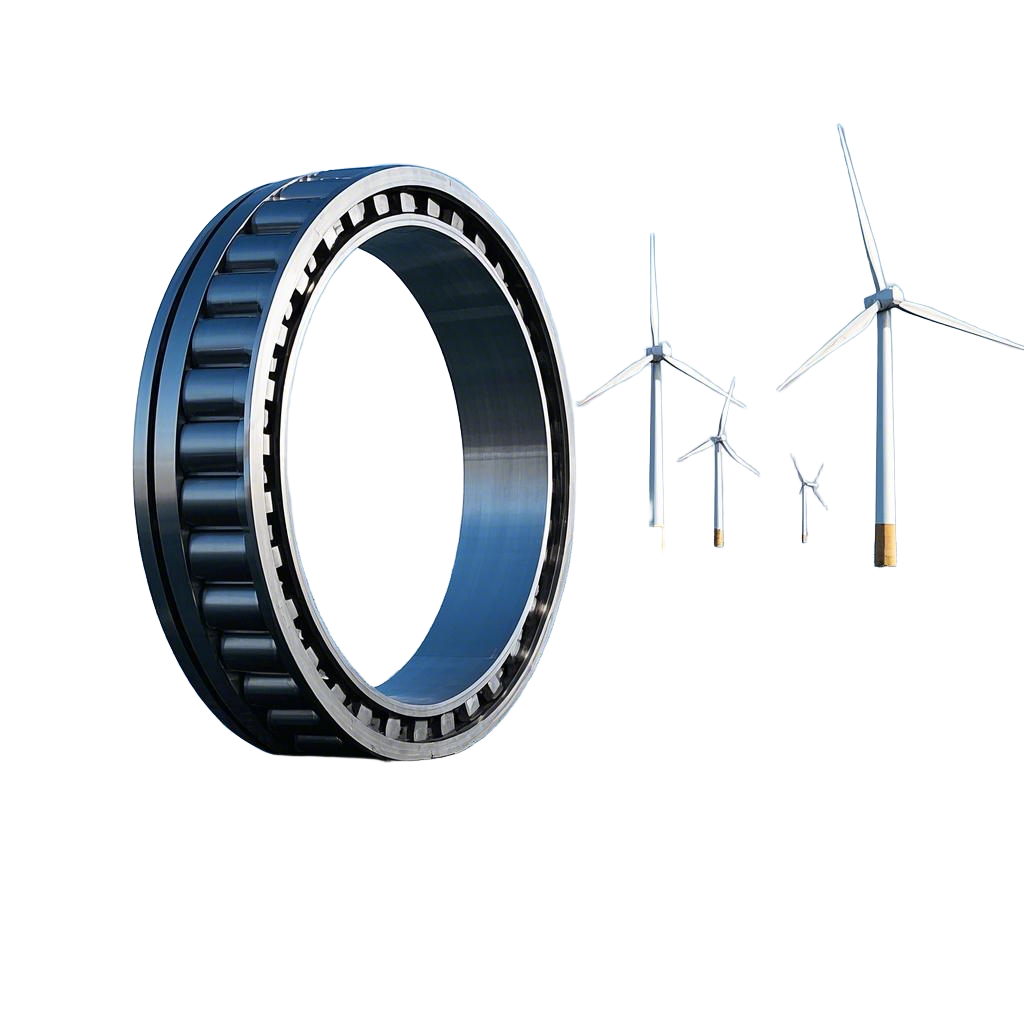

The slewing bearing is a more complex structure, which adds many balls or rollers between the inner and outer rings to form a slewing frame. This structure enables the slewing bearing to withstand not only radial and axial forces, but also significant rotational moments. In addition, the slewing bearing is usually equipped with a gear ring for rotational drive and a sealing device for dust prevention to ensure its normal low-speed and high load operation.

2、 Scope and characteristics of use

Roller bearings are widely used in various fields such as automobiles, motorcycles, aviation, petroleum, machinery, etc. due to their simple structure, light weight, and easy installation and disassembly. Different types of roller bearings play their respective advantages in different application scenarios. For example, cylindrical roller bearings are suitable for large motors, machine tool spindles, and other occasions, while self-aligning roller bearings are commonly used in heavy-duty or vibration working environments such as paper making machinery and reduction devices.

Slewing bearings are often used for the slewing bearing of large mechanical equipment such as cranes and excavators due to their ability to withstand various loads and large slewing moments. In addition, slewing bearings are widely used in construction machinery and new energy fields such as heavy-duty flatbed transport vehicles, container cranes, gantry cranes, high-altitude work vehicles, etc. Its title as the “joint of the machine” fully reflects its important position in industry.

3、 Usage environment and durability

The usage environment of roller bearings is relatively relaxed, and as long as excessive load and wear are avoided, they can be used for a longer period of time. However, under harsh working conditions such as mines, ports, oil and gas drilling platforms, the durability and anti-corrosion performance of roller bearings may not meet the requirements.

Rotary bearings require long-term operation under these harsh conditions, therefore their durability and corrosion resistance are much higher than roller bearings. In addition, due to the complex structure and high processing requirements of the slewing bearing, the production cost is relatively high. But this also gives it an irreplaceable advantage in situations that require high load and high durability.

4、 Application Cases

Roller bearings: In the automotive industry, roller bearings are widely used in key components such as engines and transmissions to ensure smooth and stable power transmission. In the aviation field, roller bearings are used in aircraft landing gear, engines and other parts to withstand huge impacts and loads.

Slewing bearing: In the crane industry, the slewing bearing is a key component for achieving the slewing of the crane boom. It can not only withstand the weight and load of the boom, but also maintain stable rotational performance under complex working conditions. In fields such as port cranes and marine cranes, the application of slewing bearings is indispensable.

5、 Summary

There are significant differences between slewing bearings and roller bearings in terms of structural form, scope of use, operating environment, and processing cost. The choice of appropriate bearing type depends on the specific application scenario and needs. In practical applications, the most suitable type of bearing should be selected based on factors such as equipment load, working environment, and maintenance requirements. This not only ensures the normal operation and efficient functioning of the equipment, but also reduces maintenance costs and operational risks.

Leave a Reply

Want to join the discussion?Feel free to contribute!