How to choose the quality, price, and service of the slewing bearing manufacturer?

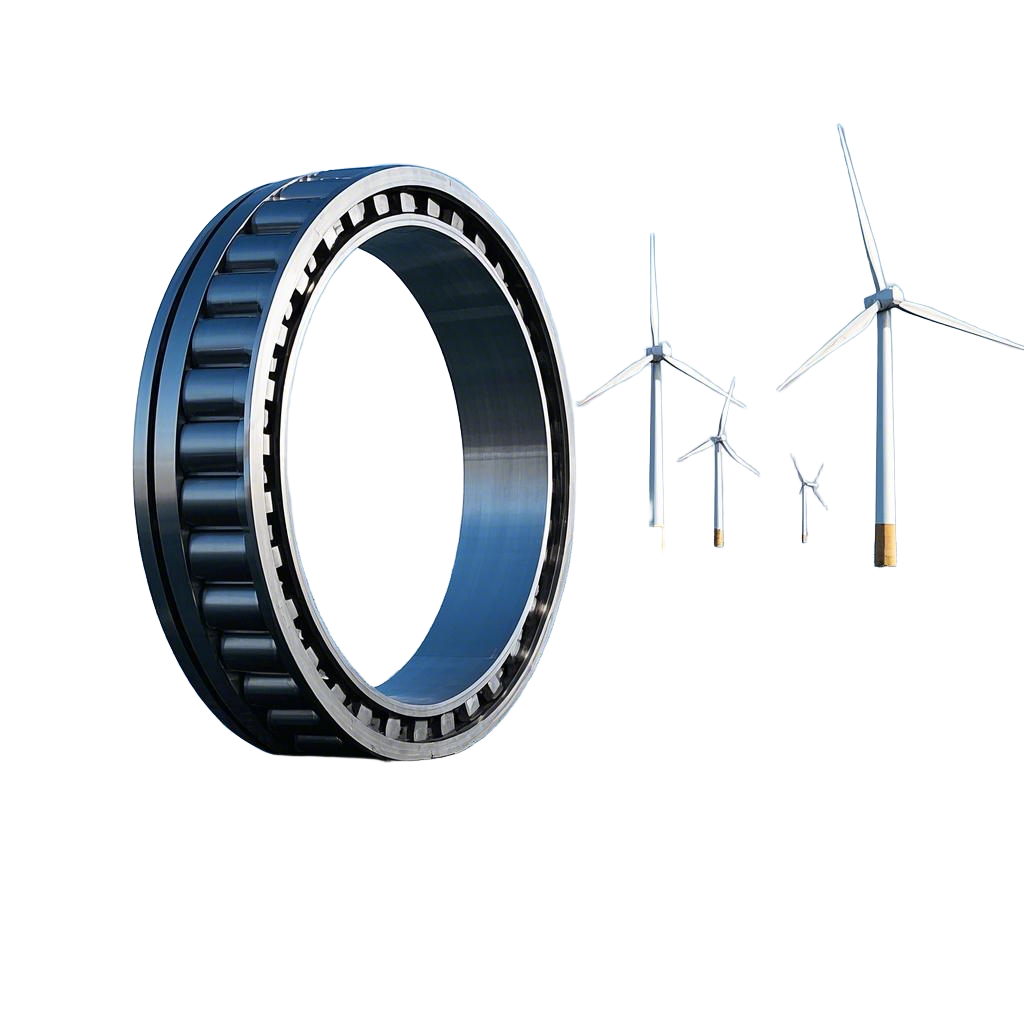

In the field of industrial equipment, as a key component for connecting and supporting large rotating structures, the quality, price, and service of slewing bearings directly affect the performance, stability, and operating costs of the entire mechanical system. Faced with numerous slewing bearing manufacturers in the market, how to make a wise choice between quality, price, and service has become an important issue for many buyers and engineers.

1、 Quality: the cornerstone of the foundation stone

Quality first, safety foremost. The quality of the slewing bearing is directly related to the service life, operational efficiency, and safety of the equipment. High quality slewing bearings should have high strength, high wear resistance, good sealing, and precise rotational accuracy. When choosing a manufacturer, special attention should be paid to its production process, raw material selection, quality control system, and historical customer feedback. Field visits, reviewing product testing reports, and understanding whether manufacturers have obtained international quality system certifications such as ISO are effective means of assessing their quality level.

2、 Price: Consideration of cost-effectiveness

Reasonable price, cost-effectiveness is king. Although price is an important factor in procurement, it is by no means the only criterion. Low prices often come with quality risks, and high prices may not necessarily represent the optimal choice. Therefore, when comparing prices, multiple factors such as product performance, quality, and after-sales service should be comprehensively considered to pursue the maximization of cost-effectiveness. At the same time, communicate fully with the manufacturer, understand their pricing strategy, and strive for reasonable price discounts and long-term cooperation conditions.

3、 Service: Ensuring Continuous Value

Service first, create a win-win situation together. Good after-sales service is an extension of product quality and a key factor in customer satisfaction. Excellent slewing bearing manufacturers should provide comprehensive pre-sales consultation, technical support, installation and commissioning guidance, and after-sales maintenance services. When making a choice, you can inquire about the manufacturer’s service response time, service network coverage, and whether they provide customized solutions. In addition, understanding the manufacturer’s customer reputation, especially the evaluation of after-sales service, is crucial for judging their service level.

4、 Comprehensively weigh and make the best decision

To make a decision between quality, price, and service, multiple factors need to be considered comprehensively and balanced. Firstly, clarify one’s own needs, including the equipment’s usage environment, operating conditions, budget range, etc; Secondly, collect sufficient information for comparative analysis through market research, on-site inspections, and communication with multiple manufacturers; Finally, based on the above analysis, combined with the company’s long-term development plan and strategic goals, make the most beneficial decision for oneself.

In short, choosing a slewing bearing manufacturer is a systematic project that requires comprehensive consideration of multiple aspects such as quality, price, and service. Only by finding the best balance between these three can we ensure the procurement of products with high cost-effectiveness, reliable quality, and thoughtful service, providing strong support for the production and operation of enterprises.

Leave a Reply

Want to join the discussion?Feel free to contribute!